Reefer Concept

It is recommended that all exporters ensure that they have a defined procedure for the maintenance & carriage of fresh produce in reefer containers. Hence, this paper is based upon the procedures adopted by Shipping Line and aims to inform our Service Provider's shipping staff, Service Provider Depots, Exporters & Packing sheds and assist a common understanding of the various components / actions that form an integrated "cold chain".

The ultimate for a fresh produce exporter is to have its product arrive at its destination in first class condition. This way the buyer is satisfied with what he or she has purchased and can confidently sell the product at optimal profit thereby generating further business for all participants in the "cold chain".

Consequently it is important and in everyone's interest to maintain the cold chain from harvesting right through to delivery to the customer.

Pre Packing Procedures

Much has been published on produce harvesting and post- harvest treatment of products, we will not attempt to add to this, thus it is assumed that all the appropriate measures / procedures have been implemented to ensure the product is at its "peak condition" when being loaded into the container.

The following are some exporter / packing shed recommended Do's & Don'ts to apply during the pre-shipment process.

1. Exporter should ensure the Shipping Line's agents are aware of the following details and the details should be provided in the booking format given:

- Name of shipper

- Size & Type of reefer

- Quantity

- Cargo type to be loaded

- Temp. setting required in °F & ° C

- Vent setting required

- Pick up date and time

- Port of delivery and final port of delivery

- Required date at port of delivery

- If IMCO, all necessary details

- Any other remarks

- Exporter instructs his transport contractor to collect the container from the nominated collection depot and ensure that the truck driver sees that the container is internally clean, has no odor, and is not damaged and the pre-trip decal (affixed to the machine casing) is still within the validity date. Under normal conditions the pre-trip is valid for 30 days (from the date shown on decal). Also it is necessary to check that the Part low chart (if applicable for the unit) is in place. If the container does not meet these conditions, the driver should not sign the EIR and he should seek another container.

- When the container arrives at the packing station, exporter to ensure the requirements defined in item have been validated again. Also ensure the drain plugs are not in place and the floor drains are open.

- Exporter to ensure that the product has been "pre-cooled" to the required carrying temperature. It is important to note: "A refrigerated container is designed / manufactured to maintain product temperature – not to reduce the product temperature to the required carrying temperature".

- Exporter to ensure that the cargo weight does not exceed the permissible cargo weight of the container, also ensure the gross weight (cargo and container) does not exceed your road regulations and those of the country of destination, the weight specifications are shown on the container door.

- Should the refrigerated container be held at exporters or his transport premises for some time (days) prior to loading the unit, it is suggested consideration be given to the refrigerated machinery. Storing an operating reefer container with the machinery facing a very hot climate causes problems with the compressor overheating, high head pressure being generated, lower refrigerating efficiency being achieved & higher running costs being incurred by direct exposure to sun light. If the ambient air is at say 40 degrees Celsius, with direct sunlight on the compressor, the compressor temperature can be as high as 50 to 60 degrees Celsius. Compressors are designed to cut out if the compressor temperature or head pressure exceeds preset limits, thus the cool chain can be broken.

Container Packing

- Ensure the product is readily available for loading and is adjacent to the container doors. I.e. ensure the container is located as close as possible to the cool room doors.

- Always load the container as quickly as possible, otherwise ambient temperature will impact on the container and the produce, usually this would be at a higher temperature, which will impact on the product quality if left for prolonged periods. If the product temperature at the time of loading is what is required for carriage during transit, then provided the container is loaded quickly the product temperature will quickly disperse the internal ambient air, therefore the container can operate effectively & efficiently.

- If loading does not occur in a "cold tunnel", do not pre cool the container, it is a waste of power & serves no purpose because the ambient air temperature will invade the container within minutes of the doors being opened. Furthermore if pre cooled, when the ambient air mixes with the chilled air, condensation will occur on the container internal walls. When the container is operational again, the condensation accumulated will force the machinery to more than regularly "defrost", this will result in heat being introduced to take off the ice formed on the evaporator coils – not conducive to maintaining the required chiller temperature. This also adds pressure on the machinery to perform, which with excessive demand, could result in a failure of the machinery. Furthermore, condensation could accumulate on the product cartons, resulting in wet / collapsed packaging.

- Image - Cargo should be stowed below the red line.The cargo must never be loaded above the red line of the container, if cargo exceeds the red line this will impede the air flow which could impact on the quality product out turn and possibly the refrigeration unit.

- Ensure that the weight is evenly distributed throughout the floor space.

- If using forklifts to load the product, ensure that the "T" bar floor grills are protected from damage, as any damage could cause restricted air flow during the transit to the buyer and impact on the quality out turn.

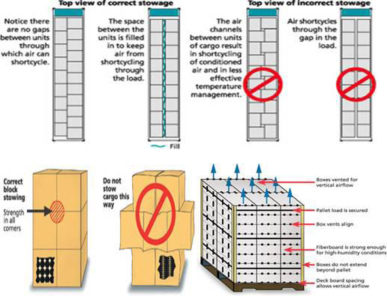

- Ensure that the packages are stowed with adequate spacing between the packages for "good" air flow and that the storing is stable. Do not leave large spaces

where the stow could collapse during transit. Palletisation gives a much improved air flow.

- If the container is being held on power at the packing station, before transport to the terminal, ensure:

Carriage temperature is set to the required setting. NB, THIS IS THE SUPPLY AIR TEMPERATURE SETTING.

The fresh air vents are open to the setting required.

The Part low chart is "face up" ready to record & the needle is in the correct position. THIS IS THE RETURN AIR READING, usually slightly higher than the supply air because of produce respiration. When there is a stable temperature, i.e. immediately after being placed on power, the initial Part low chart readings can be much higher than the supply air setting, because the container must disperse the respirated heat & ambient air that has accumulated during the packing of the container. Shippers / Packers are urged to use a bolt seal in addition to any other seals required by the Shipper or Government authorities. However if the container is subject to " PULP TESTING ", please use a strip seal as the bolt seal will be utilized after the pulp testing – as per the pulp testing instructions

Transport & Terminal Receival

- Ensure the vehicle is suitable to transport the container, particularly handling the gross weight and has suitable twist lock fittings – chains are not acceptable. Always ensure that reefer unit power cable is correctly stored within the unit casing, especially if the container was "on power" prior to the transport to the Terminal.

- All appropriate export permits / approvals must be completed before the vehicle leaves the packing station and handed to the driver. The Shipping Line Agent should send an Export Receival Advice (ERA – Ref. appendix 2) to the POL for the acceptance of export reefer. A completed ERA should have all the following information (is clearly written so there is no mis-interpretation of what has been written) – Container no/s, type & size, booking no., seal no., shipper's name, commodity, weight, vessel, voyage number & Eta, POL/POD, set temperature, vent setting, Humidity and IMCO details (if any). Same should be forwarded to the vessel operator and obtain the acknowledgement from vsl. Operator / Chief. Officer for future reference.

- If being transported under refrigeration (i.e. generator), ensure the machinery is set correctly (as per h above). However, ensure the vents are closed during the transport movement to avoid pollutants / contamination i.e. diesel fumes from entering the container via the vents during the transport journey. Usually the container machinery end is loaded behind the transport cabin.

- If not being transported under refrigeration, the transporter must travel directly to the terminal. Transport of more than 2 to 3 hours (without refrigeration) will result in increased product temperature due to the product respiration during the transit. It has been shown in recent exercises that during the transport (during early morning) that the pulp temperature of produce increased by 3 to 4 degrees Celsius during a 6 hour transit – not conducive to a good product out turn!

- Exporter must always ensure that his transport contractor has sufficient time to arrive at the terminal before the final Receival time. Exporter must check with the Shipping Line agent office for the final Receival times and if a late Receival is available on that particular day of delivery. Normally the Terminal final Receival times for refrigerated cargo is 1 hour before closure, this enables the container to be placed on power and checked to ensure the unit is operating correctly.

- When the transport arrives at the Terminal, providing the ERA is completed correctly, the transport will be directed to the unloading area – if the ERA is not completed, the transport will be rejected & "turned away".